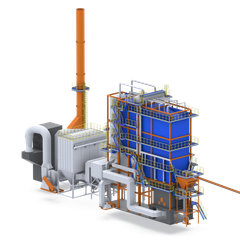

This is a burning technology on an endlessly moving recording surface and the fuel layer moves simultaneously with the recording. The chain grate is moved from front to back thanks to the transmission shaft (located in the front). The transmission shaft is driven by an electric motor through a gear reduction box. During the recording movement from front to back, the stages of fuel combustion occurred one after another and occupied certain regions along the recording length. Air supplied for the combustion process is blown from bottom to top by fans passing through the air vents. To distribute air evenly across the recording surface, tongue-shaped shields are placed in the air vents. Chain grate burners will work effectively with fuel that has a uniform particle size, not too large.

| Design standards | : According to ASME and TCVN standards |

| Manufacturing standards | : According to ASME and TCVN standards |

| Steam generation capacity | : 1,000 - 40,000 Kg/hour |

| Design pressure | : 10 - 150 bar |

| Steam parameters | : Saturated steam or superheated steam |

| Boiler efficiency | : 85 ± 2 % |

| Fuel | : Indonesian coal bran, 4A bran, firewood pellets, rice husk pellets, chopped firewood,... |