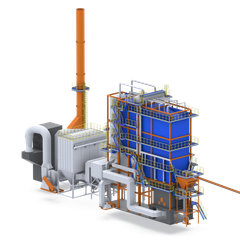

This is a technology that burns on a fixed grate, putting fuel into the fire chamber manually. Fuel is fed through the furnace door into the grate, the new fuel placed on top of the burning old fuel. The air supplied for the combustion process is blown from the undercarriage through the ash layer, heated to a certain temperature, and at the same time has the effect of causing some unburned coke in the slag to continue to burn out. The heated air will then provide oxygen to the burning coke layer. Static burners work with many different sizes of fuel, especially large ones.

| Design standards | : According to ASME and TCVN standards |

| Manufacturing standards | : According to ASME and TCVN standards |

| Steam generation capacity | : 1,000 - 20,000 Kg/hour |

| Design pressure | : 10 - 150 bar |

| Steam parameters | : Saturated steam or superheated steam |

| Boiler efficiency | : 80 ± 2 % |