Explain in detail the dust system of the boiler

As we know, when solid fuel is burned, a large amount of dust is generated, and if not treated, the exhaust will cause serious pollution to the surrounding environment. Therefore, equipping suitable dust filtration systems for boilers is extremely necessary.

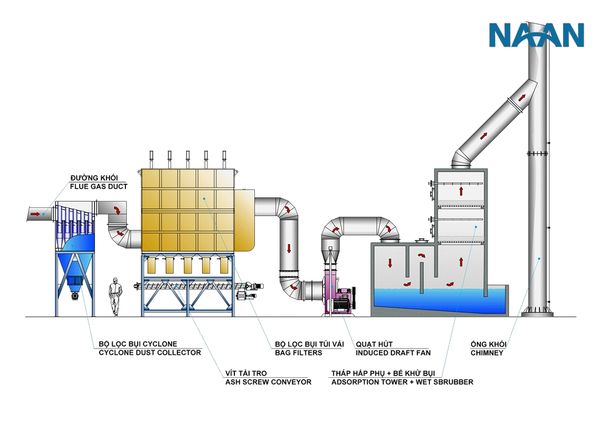

Sơ đồ hệ thống lọc bụi trong nồi hơi công nghiệp

- Cyclone Dust Filter: Uses centrifugal force to separate dust from gas, with high efficiency and low operating costs.

- Wet Dust Filter: Uses liquid, usually water, to separate dust from the air.

- Cloth Bag Dust Filter: Has high dust filtration efficiency, suitable for minimizing dust emissions from industrial furnaces.

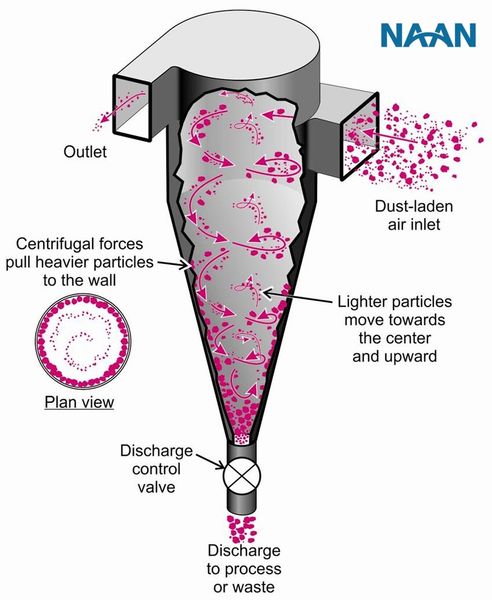

1. Cyclone Dust Filter

Nguyên lý thu bụi của cyclone

The cluster cyclone dust collector operates based on the principle of centrifugal force, where air and dust are sucked into the device and move along a circular spiral trajectory. As the air and dust flow, heavier dust particles will be pushed away from the axis by centrifugal force and collide with the walls of the device, then fall into the ash hopper at the bottom. This filter has high efficiency, can collect over 95% of flying dust and is suitable for use in industrial boilers, especially with boilers burning straw, sawdust, or coal. Cluster cyclones are also designed to withstand high temperatures, pressures, and abrasion, making them an effective solution for industrial exhaust treatment.

Advantages of cluster cyclone dust collectors:

- Simple structure, capable of continuous and stable operation even under temperatures up to 300°C.

- Dust is collected in dry form, making it easy to handle and reuse.

- Moreover, this filter has stable resistance, ensuring high efficiency during operation and does not require frequent maintenance.

- This makes cluster cyclone dust collectors an economical and sustainable choice for factories and manufacturing facilities.

2. Wet Dust Filter

Wet dust suppression tanks are installed to treat dust before being discharged into the environment

The wet dust collector is a system designed to remove dust particles from the air using liquid, usually water. The operating principle of the wet dust collector is based on using a fan to suck dust-containing air into the system. As the air passes through the filter, dust particles are retained by the liquid and then separated from the airflow as sludge or sediment. This system can effectively remove both fine and coarse dust particles while also minimizing the risk of dust re-emission into the air. Wet dust collectors are commonly used in heavy industries such as steel production, cement, and thermal power plants, where dust control is crucial to protect the environment and human health.

Advantages of Wet Dust Filter:

- The main advantage of this system includes the ability to effectively remove up to 90% of dust, including ultra-fine particles, while also treating both dust and hazardous exhaust gases such as SO2 and NOx.

- Wet dust filtration systems can handle high-temperature exhaust, do not cause dust re-emission, and have low initial investment costs.

- In addition, the system is designed to be simple, easy to operate and maintain, making it an optimal choice for various industries.

3. Fabric bag dust collector

The cloth bag dust filter is installed in series after the beam cyclone dust filter

The fabric bag dust collector is an important device in industrial exhaust treatment, helping to remove dust and impurities from the air before releasing it into the environment. Its operating principle is based on using fabric bags as traps to capture dust particles. Exhaust gases from the factory are directed into the filter chamber, which contains fabric bags. As the gas passes through, larger dust particles than the size of the fabric bag's holes are trapped, while clean air is allowed to pass through. This process not only helps clean the air but also minimizes the impact on the environment and human health. To maintain efficiency, fabric bags need to be cleaned or replaced regularly to avoid clogging and maintain stable exhaust flow.

Advantages of fabric bag dust collectors:

- The ability to filter dust at low concentrations, filter various types of dust, and easy to install and operate.

- The filter material has a reasonable cost, contributing to reducing initial investment costs.

- High filtration efficiency, can reach from 90% to over 99%, along with low maintenance and operating costs are factors that make this equipment popular.

- Furthermore, fabric bag dust collectors can recover dust in dry form, allowing for reuse and minimizing the amount of waste released into the environment.