Water supply tank and common mistakes when choosing a water supply tank

Horizontal feed water tank placed on a stand to increase pump head

1. Main function of boiler feed water tank

The main function of a boiler feed water tank is to store and supply water for the steam production process. It helps maintain the water level in the boiler at a stable level, thereby ensuring continuous and efficient steam production.

Functions of the boiler feed water tank in the boiler:

- Recovery of condensed water and flash steam to save energy

- Use of steam injection to control the temperature of the feed water tank, reducing the amount of chemicals required

- Reduction of dissolved oxygen from the feed water, thereby eliminating boiler and pipe corrosion

- Storage of sufficient feed water volume to ensure a constant and stable water supply for steam generation when needed.

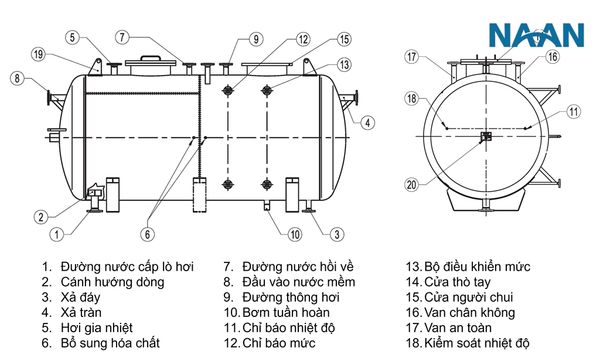

A standard boiler feed water tank design

- Preventing boiler damage: A boiler undergoes thermal shock when cold water is introduced to the hot surfaces of the boiler shell and heat exchange tubes inside the boiler. Higher feed water temperatures mean lower temperature differentials and less risk of thermal shock.

- Maintaining boiler design capacity: The lower the temperature of the feed water to the boiler, the more energy the boiler consumes to produce steam. It is important to maintain the feed water temperature as high as possible to maintain the required steam output.

- Preventing pump cavitation: Care must be taken when managing the feed water temperature, as a very high condensate return rate can lead to excessively high feed water temperatures, which can cause cavitation of the boiler feed water pump.

2. Types of boiler feed water tanks

There are two main types of boiler feed water tanks used in boiler systems, namely horizontal and vertical tanks. Each type of tank has its own advantages and disadvantages, suitable for specific boiler systems.

Horizontal tanks, with a horizontal design, are often preferred in systems with limited height space. The advantage of this type of tank is easy installation and maintenance, as well as the ability to distribute water evenly over the surface of the boiler, optimizing heat transfer. However, the disadvantage of horizontal tanks is that they occupy more space and may not be suitable for systems requiring high water pressure.

Vertical feed water tank design saves space

On the contrary, vertical tanks, with a tall and slender design, are suitable for spaces with unlimited height. Vertical tanks have better pressure resistance and are often used in systems requiring high water pressure. Additionally, this type of tank saves horizontal space. However, installation and maintenance may be more difficult compared to horizontal tanks due to higher technical requirements and limited access.

Choosing the appropriate type of feed water tank is important to ensure efficiency and safety for the entire boiler system. Factors such as installation space, capacity, pressure requirements, and ease of maintenance need to be carefully considered to make the most appropriate decision.

3. Common mistakes when selecting a boiler feed water tank

In the process of selecting a boiler feed water tank, there are some common mistakes that businesses often encounter. These are points to note to avoid undesirable consequences.

1. Incorrect calculation of required water volume: Failure to accurately determine the amount of water needed for the boiler operation can lead to water shortages, causing overheating and damage.

2. Overlooking safety factors: Safety is a top priority in designing any system, and the boiler feed water tank is no exception. It must be ensured that the tank is equipped with safety devices such as safety valves, water level sensors, and alarm systems.

Damage to the feed water tank during operation due to incorrect design and operation

3. Failure to calculate working pressure: The working pressure of the feed water tank must be compatible with the boiler pressure. If the pressure is not accurately calculated, it can lead to issues with water supply and boiler performance.

4. Choosing inappropriate materials: Using materials that cannot withstand high pressure or temperature can cause leaks and even tank ruptures.

5. Neglecting maintenance considerations: The feed water tank should be designed for easy maintenance and repair to extend the lifespan of the equipment.

Above are some common mistakes that businesses should avoid when selecting a boiler feed water tank. Paying attention to these points will help increase operational efficiency and safety for the entire system.