Boiler distillation and extraction process in the cooking oil industry

Oil bottling process (Image: Kernel.ua)

Did you know that a boiler is an indispensable device in the production of cooking oil? Boilers play a crucial role in the distillation and extraction process of various vegetable oils from ingredients such as soybeans, rapeseed, flaxseeds, etc. In this article, we will introduce you to the distillation and extraction process using a boiler, as well as the excellent applications of boilers in the cooking oil production industry.

1. Distillation and Extraction Process Using a Boiler

The distillation and extraction process using a boiler is an efficient method for separating valuable components from plant-based raw materials. This process consists of two main steps: distillation and extraction.

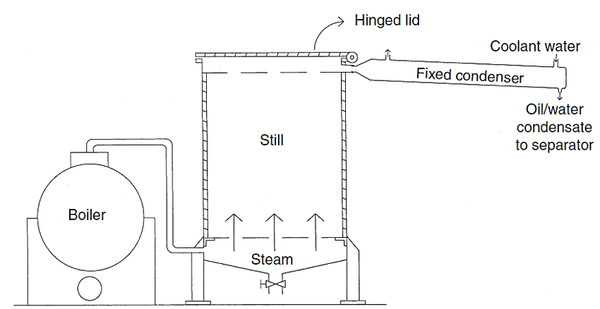

Steam distillation process with a separate boiler (Source: ResearchGate)

Distillation is the process of heating plant-based raw materials to produce steam, which is then condensed to obtain high-value liquid substances. Distillation can be performed in various ways, but the most common method is using a boiler. The boiler is a thermal device that uses fuels such as coal, gas, or oil to heat water in a container. The hot water is then fed into a conduit to come into contact with plant-based raw materials in a device called a distillation machine. Here, the hot water will vaporize low-boiling-point components in the plant-based materials, such as oil, terpenes, phenols, etc. The steam carrying these components is directed into a condensation device, where the steam is cooled to become a liquid. This liquid is then separated into different phases based on the density and solubility of the components. For example, oil will separate into a distinct phase due to its lower density and insolubility in water.

Extraction is the process of using a solvent to dissolve valuable components from plant-based raw materials. Extraction can be carried out in various ways, but the most common method is using a boiler. Boilers can also be used to generate vapor-phase solvents such as hexane, ethanol, etc. These vapor-phase solvents are fed into an extraction machine, where the solvent comes into contact with plant-based raw materials under appropriate pressure and temperature conditions. Here, the solvent will dissolve high-value components in the plant-based materials, such as oil, protein, vitamins, etc. The solvent carrying these components is then directed into a solvent recovery device, where the solvent is condensed back by cooling. The high-value components are obtained as a liquid or powder.

2. Applications of Boilers in the Cooking Oil Production Industry

Boilers in the cooking oil production industry

Boilers are a crucial device in the cooking oil production industry. Boilers not only help generate steam and vapor-phase solvents for the distillation and extraction processes but also have many other applications, including:

- Boilers enhance the efficiency and quality of the distillation and extraction process by providing stable heat and pressure to related equipment.

- Boilers save energy and minimize environmental pollution by reusing hot water and vapor-phase solvents for subsequent cycles of the distillation and extraction processes.

- Boilers create high-value by-products from plant-based raw materials using steam and vapor-phase solvents for sterilization, drying, or breaking down unwanted components in plant-based materials. For example, boilers can produce soybean meal from soybeans, serving as a feed or biomass ingredient.

Therefore, boilers are a versatile and efficient device in the cooking oil production industry. Boilers not only help produce high-quality vegetable oils from plant-based raw materials but also maximize the utilization of plant-based materials and protect the environment. Would you like to learn more about boilers and their applications in the cooking oil production industry? Contact us for the best advice and support!