Boiler for the paper industry - Burning industrial waste meeting standard QCVN30

The paper industry is one of the strongly developing fields in Vietnam. Data from the Vietnam Pulp and Paper Association (VPPA) shows that in 2022, Vietnam's paper and pulp output will reach 4.5 million tons, an increase of 10% compared to 2021.

The rapid development of the paper industry is accompanied by an increase in the amount of waste. According to VPPA statistics, the amount of waste from the paper industry in 2022 will reach about 1.5 million tons, accounting for 33% of the total amount of household waste in the country.

Image of waste from the paper industry

Waste from the paper industry includes many types, mainly scrap paper, fiber, wood chips, bark,... Most paper industry waste can be treated by burning. . Burning waste is considered an effective solution to reduce environmental pollution caused by paper industry waste. This process brings many benefits, including:

- Reducing the amount of waste generated: Waste after being burned will turn into reusable energy in paper production , helping to reduce the total amount of waste.

- Reduce environmental pollution: Although the combustion process can create harmful emissions, if strictly controlled, these emissions can can be significantly reduced.

- Cost savings: Burning waste helps reduce waste treatment costs and provides energy for the paper industry.

< strong>1. Industrial waste burning boiler meets standard 30

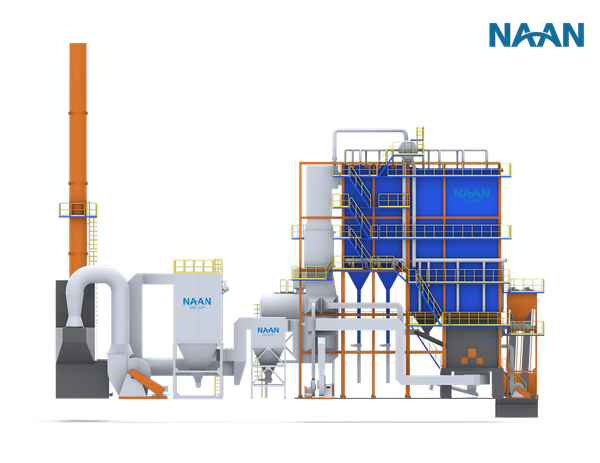

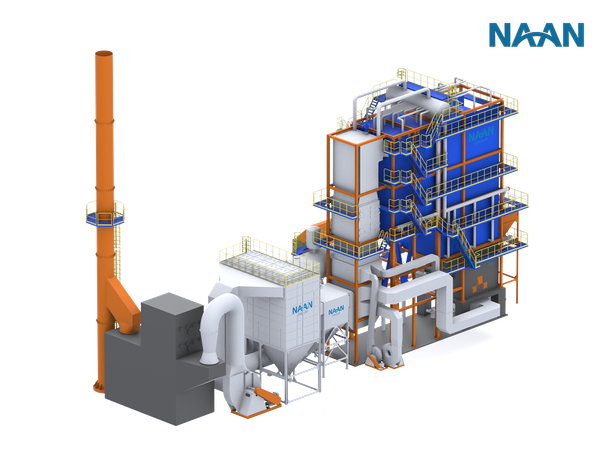

Fluidized bed boiler Naan - Industrial waste burning boiler meets standard 30< /p>

Industrial waste burning boilers meeting standard 30 are considered an effective and sustainable solution for waste treatment and energy production in the paper industry. Benefits of this type of boiler include:

- Reducing industrial waste buried or discharged into the environment, protecting the environment and public health.

- Take advantage of renewable fuel sources from waste, reduce fuel costs and increase economic efficiency.

- Produce steam with high temperature and pressure, meeting the needs of paper production .

- Comply with emission and product quality standards of the Ministry of Industry and Trade and regulatory agencies.

To achieve high combustion efficiency industrial waste, it is necessary to pay attention to the following issues:

- Choose the type of boiler suitable to the characteristics of industrial waste and the needs of the business.

- Control the combustion process to ensure efficiency and minimize environmental pollution emissions.

- Treat exhaust gases before being released into the environment.

2. What is Regulation 30?

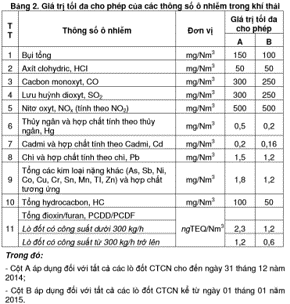

Regulation 30 is the short name for the National Technical Regulation on boiler emissions (QCVN 30:2012/BTNMT), Regulation 30 sets sets limits for pollution parameters in boiler exhaust gases and basic requirements for environmental protection.

According to QCVN 30-2012: National technical QC on industrial waste incinerators

To achieve standard 30, the following measures need to be taken when treating exhaust gases:

1. Primary treatment aims to remove solids, liquids and vapors larger than a certain value.

- Dust filter: Use dry dust filter or wet dust filter.

- Condensation: Condensation of water vapor in the exhaust gas.

2. Secondary treatment to remove contaminants whose size is less than a certain value.

- Minimize NOx: Use methods to minimize oxygen, temperature, or air retention time in the combustion chamber.

- Minimize SO2: Use fuel desulfurization or exhaust gas treatment.

3. Thorough treatment to completely remove pollutants in boiler exhaust gases.

- Absorption: Use absorbent to remove pollutants.

- Air separation: Use air separation equipment to separate pollutants.

Choosing a boiler exhaust gas treatment method should be based on exhaust gas composition, boiler capacity, and emissions standards. Compliance with standard 30 is mandatory and needs to be strictly implemented to reduce environmental pollution and protect human health.

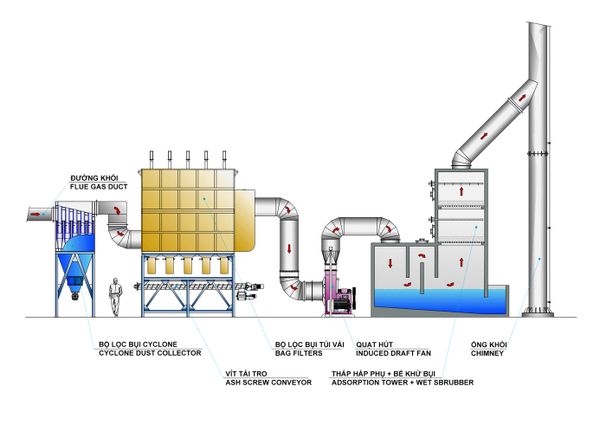

3. Boiler exhaust gas treatment process meets Naan's Standard 30

Boiler exhaust smoke treatment process meets QCVN 30-20 12

For environmental issues, Naan has researched and designed a Cyclone beam dust suppressor for use in boilers. This dust suppressor has been proven to be effective on all Naan boilers, ensuring the capture of over 90% of airborne ash. smoke.

The beam Cyclone dust suppressor is a beam of single cyclones, using centrifugal force to separate dust particles. The smoke stream enters the beam Cyclone and is then evenly distributed to the particles. Cyclone. Large dust particles are pushed radially towards the wall of the Cyclone element and are then separated and sent down to the ash collection hopper. The smoke stream is discharged after passing through the bottom part of the Cyclone element.

The cloth bag dust filter is used after the Cyclone beam dust suppressor to thoroughly treat the environment. . The smoke flow after exiting the Cyclone enters the cloth bag filter from below and from the outside inside the bag. Large dust particles are retained on the bag surface, while smaller particles adhere to the filter fabric fibers, achieving 99% filtration efficiency.

The fabric bag dust filter is controlled by differential. Pressure or timer to remove dust. The dust removal process is performed by spraying compressed air directly into the bag, cleaning the dust layer and ensuring high filtration efficiency. Dust settles into the dust collection hopper and is discharged through the rotating valve periodically.

In short, both Naan's Cyclone beam dust collector and cloth bag dust filter are designed for efficiency. Superior in removing dust and ash from smoke streams, while ensuring a clean and safe working environment.

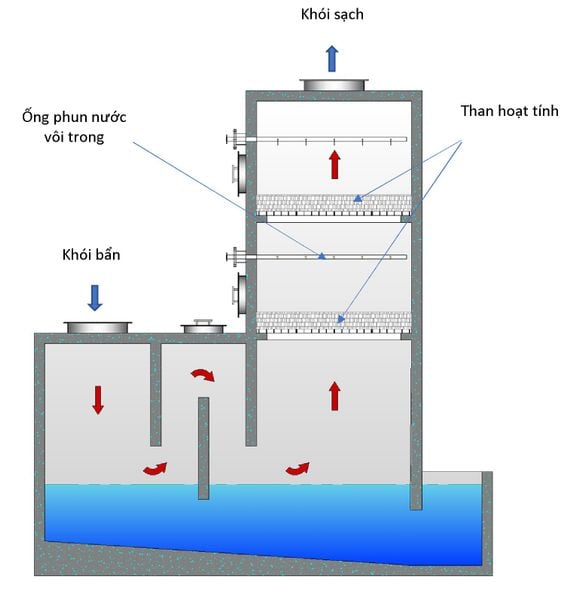

Absorption tower - SOx, NOx removal device

In the absorption tower, the absorption solution is pumped from the top of the tower down to help the contact process between gas and solution take place easily. The absorption tower uses Ca(OH)2 solution, this solution has a Ca(OH)2 content of 100-110 g/liter and is supplied from metering pump system. Clean gas, after passing through the absorption tower and reaching standard 30, will be discharged through the chimney.

The absorption solution is circulated and checked regularly, with additional Ca ( OH)2 to ensure absorption efficiency. Each month, this amount of solution will be discharged into the wastewater treatment system. Ash and slag from the boiler fuel combustion process are collected and transferred to the collection unit for treatment according to regulations.

4. Naan Fluidized Bed Boiler

The fluidized bed boiler, designed by Naan, is a leading solution for the paper industry and industrial waste treatment, especially especially in meeting environmental standards such as Vietnam Regulations QCVN 30. Naan has set a high standard in developing and providing fluidized bed boilers with special features and advantages to meet increasing demands for performance, safety and environmental protection.

Fluidized Bed Boiler Naan - Waste Burning Boiler industry meets standard 30

Naan's fluidized bed boiler is the preferred choice in the paper industry with the ability to process industrial waste. This boiler's unique design optimizes combustion and energy generation, while minimizing emissions and environmental impact. In particular, this boiler meets QCVN 30, the standard regulating air quality and emissions, making it a safe and effective choice for businesses in the paper industry.

Furnace fluidized bed steam Naan - Industrial waste burning boiler meets standard 30

With the ability to burn effectively and control exhaust smoke, Naan's fluidized bed boiler not only helps optimize the production process but also actively contributes to environmental protection. This makes it a comprehensive and sustainable solution for paper and industrial waste processing businesses, while meeting the strict requirements of environmental standards and regulations.