Integrating automation systems into industrial boilers

Integration of Automation System into Industrial Boilers

Industrial boilers are crucial equipment in various manufacturing industries such as textiles, food, paper, chemicals, energy, etc. Boilers function to convert fuel into steam, providing heat and pressure for various processes. However, operating and maintaining boilers require significant effort and costs, with inherent risks to safety and the environment. Therefore, integrating an automation system into industrial boilers is an efficient and cost-saving solution, bringing many benefits to businesses.

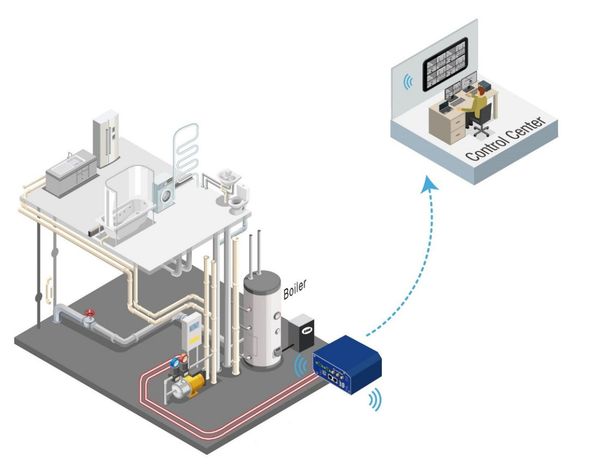

The automation system for industrial boilers utilizes electronic devices and computer-controlled mechanisms to oversee boiler processes, including startup, shutdown, temperature and pressure adjustments, water level control, fuel combustion, safety protection, etc. The automation system can operate independently or connect to a central management system for remote monitoring and control.

Remote Monitoring System for Boilers

1. Components of the Industrial Boiler Automation System

Industrial boilers are complex systems with many synchronized components. Integrating an automation system into industrial boilers enhances safety, efficiency, and stability in operation.

The key components of the industrial boiler automation system include:

- Sensors: Sensors are devices used to collect information about the status of equipment in industrial boilers. Commonly used sensors in industrial boilers include: * Temperature sensors * Pressure sensors * Flow sensors * Water level sensors * Oxygen sensors * Smoke sensors

- Controllers: Controllers receive information from sensors and send commands to actuators. Controllers commonly used in industrial boilers include: * PLC controllers * SCADA controllers

- Actuators: Actuators execute commands from controllers. Common actuators used in industrial boilers include: * Control valves * Pumps * Motors * Fuel burners

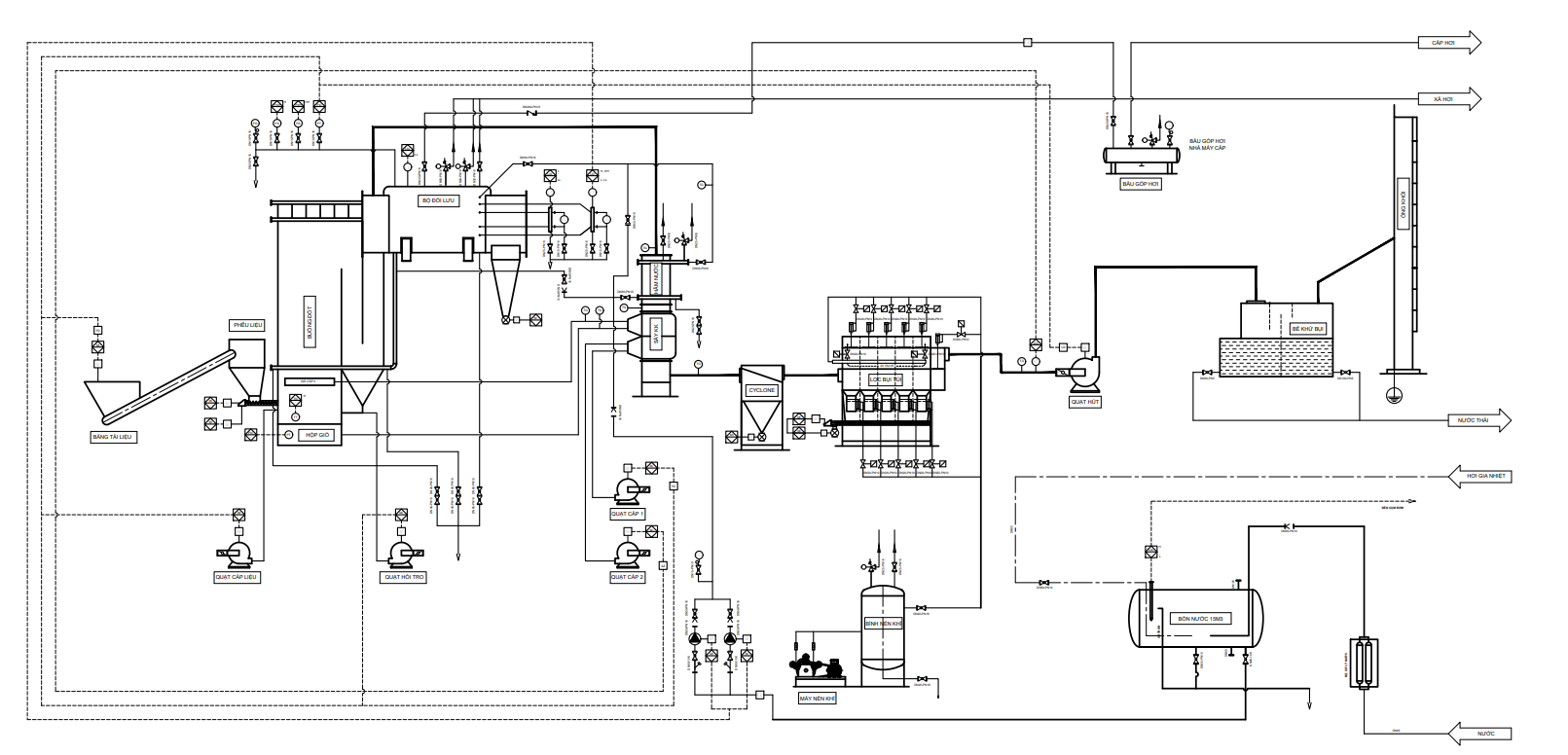

Control P&ID for Steam Boiler

Control P&ID for Steam Boiler

2. Applications of Automation System in Industrial Boiler Operations

The automation system can be applied in various areas of industrial boiler operations, including:

- Control of Temperature, Pressure, Flow: The automation system helps regulate temperature, pressure, and flow in industrial boilers at stable levels, meeting production process requirements.

- Fuel Supply Control, Water Supply Control: The automation system ensures accurate and timely fuel and water supply to industrial boilers, ensuring stable fuel combustion and consistent steam supply.

- Ash Discharge Control: The automation system helps safely discharge ash from industrial boilers without causing environmental pollution.

- Safety Control: The automation system can detect and alert incidents during industrial boiler operations, ensuring safety for operators and equipment.

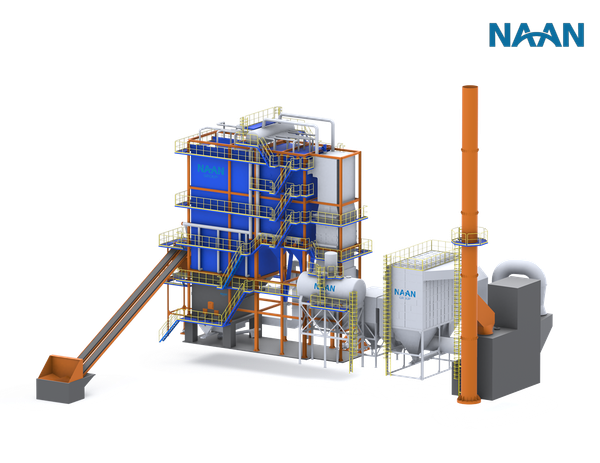

Automation of Fuel Supply and Ash Discharge

3. Benefits of Integrating Automation System into Industrial Boilers

Integrating the automation system into industrial boilers brings various benefits, including:

- Increased Productivity and Production Quality: The automated boiler system produces high, stable, and precise steam and heat, meeting the requirements of different production processes. The system also minimizes human errors, operational mistakes, downtime, etc., enhancing efficiency and reliability.

- Energy and Cost Savings: The automated boiler system can adjust fuel, temperature, pressure, water level, etc., according to preset settings or real-time conditions, optimizing fuel combustion efficiency, reducing fuel consumption costs, and minimizing environmental pollution-related costs.

- Ensuring Safety and Equipment Protection: The automated boiler system can detect and alert incidents such as overheating, overpressure, water shortage, leaks, explosions, etc., activating safety devices such as safety valves, backup pumps, fire extinguishers, etc., to prevent and address issues promptly. The system also helps protect boiler equipment from damage, prolonging its lifespan and reducing replacement costs.

Naan Steam Boiler - Perfect Automation

At NAAN Corporation, we specialize in designing, manufacturing, and installing various types of industrial boilers, including steam boilers, thermal oil boilers, static pressure boilers, heat recovery boilers, etc., with capacities ranging from 0.5 ton/h to 100 ton/h, pressures from 0.4 MPa to 9.8 MPa, temperatures from 150°C to 540°C, burning various fuels such as coal, oil, gas, husk, waste, etc. We also provide integrated automation system solutions for industrial boilers, tailored to the requirements and conditions of our clients, ensuring the highest efficiency for businesses.

If you are interested in our products and services, please contact us at 0974022345 or email am@tpeg.vn. We will provide attentive advice and reasonable quotations. Thank you for reading this article, and we hope to soon have you as our valued customer.