Learn about the water heater in the boiler

Bộ hâm nước trong lò hơi

1. What is the function of the water heater?

The water heater is a heat exchanger that uses boiler waste heat to heat supplied water. The water heater absorbs exhaust heat, reduces exhaust temperature, improves boiler efficiency, and saves fuel. Additionally, because water is supplied to the boiler drum, the water temperature is increased through the water heater, reducing the thermal stress of the boiler drum due to temperature differences, thereby improving the working conditions of the boiler drum and extending the life of the boiler drum.

2. What is a non-boiling water heater?

A non-boiling water heater means that the final temperature of the supplied water after being heated by the water heater reaches the saturation temperature (meaning it does not reach the boiling state), usually 30 ~ 50C lower than the saturation temperature.

3. Why do modern large boilers use non-boiling water heaters?

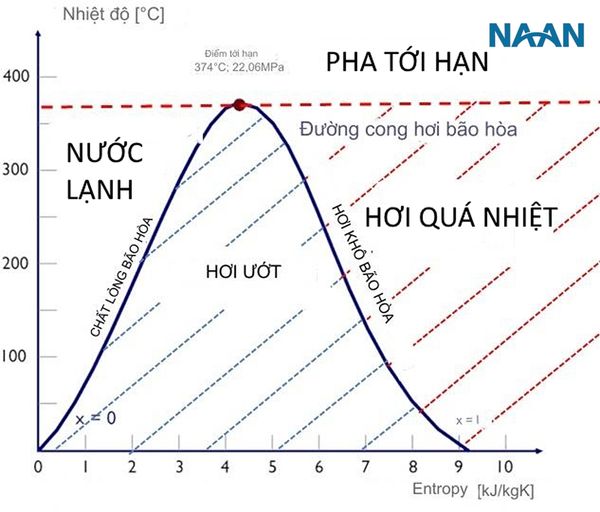

Water vapor characteristic graph

From the characteristic graph of water vapor, with the increase of parameters, the latent heat of vaporization (latent heat) required for saturated water to become saturated vapor decreases, and the total heat increases. Therefore, the heating surface of the boiler steam generator is reduced, and the heating surface area (economizer) required to heat the working liquid heat increases. The higher the boiler parameters, the larger the capacity, the size of the boiler and the heat release of the boiler increase, in order to prevent slagging of the boiler and ensure the safe operation of the boiler, sufficient heating surface must be arranged in the boiler to reduce the exhaust gas temperature of the boiler to the allowable range. To achieve this goal, a part of the water heat is transferred to the boiler evaporative heating surface, equivalent to the heat absorption task of the water heater. In addition, the water heater heating surface mainly relies on convective heat transfer, while the boiler relies on radiant heat transfer. Heat transfer per unit heating surface area of radiant heat transfer (water-cooled wall) is much greater than that of convective heating surface system (water heater, etc.). Therefore, transferring the heat transfer task of the liquid to the boiler heating surface can significantly reduce the number of heating areas of the entire boiler, reduce steel consumption, and reduce boiler construction costs;

In addition, increasing the temperature to near boiling point of the supplied water is very beneficial for the circulation of boiler water. Therefore, the economizer of large-capacity and high-performance boilers is often designed to be non-boiling.

4. How is the erosion of the water heater surface formed? What factors are related?

The erosion of the water heater surface is caused by the melting particles along with the exhaust gas, having a certain kinetic energy and formed by scraping small metal pieces whenever it touches the tube wall.

The main factors are:

- (1) Fly ash velocity: The amount of metal erosion in the heat exchanger tube is directly proportional to the kinetic energy of the ash particles colliding with the tube wall and the number of collisions. The kinetic energy of the ash particles is proportional to the square of the exhaust gas velocity, so the amount of erosion on the tube wall is proportional to the square of the exhaust gas velocity.

- (2) Fly ash concentration: The higher the fly ash concentration, the more the ash particles will impact and the more serious the erosion will become. Therefore, the erosion of fuels with high ash content becomes more serious.

- (3) Characteristics of ash particles: The coarser and harder the ash particles are, the more edges and corners they have, and the more severe the erosion.

- (4) Construction characteristics of tube bundles: Erosion of exhaust gas when tube bundles are washed vertically is much lighter than when washed horizontally. This is because the ash particles move in the direction of the tube axis and the likelihood of impacting the tube wall is significantly reduced. When the exhaust gas is washed horizontally, the erosion of the tube bundle is much greater than that of the sequential tube bundle.

- (5) Fly ash impact velocity. The ability of fly ash to impact the tube wall is determined by many different factors. The impact velocity of fly ash is large if the fly ash particles are large, heavy fly ash, and the exhaust gas velocity is fast.

5. Which parts of the water heater are prone to erosion?

- (1) When the exhaust gas enters the vertical flue, which is arranged with the water heater from the horizontal flue, due to the centrifugal force generated by the swirling flow of the exhaust gas, most of the ash particles are thrown into the rear wall of the tail flue, so the fly ash concentration in this part increases significantly, leading to severe erosion of the economizer near the wall behind the boiler, the part close to the wall being eroded more.

- (2) When there is a large gap between the close pipe and the water heater wall or there is an exhaust gas alley between the rows of pipes, the flow resistance of the exhaust gas in the alley is much smaller than that in other places. The flow velocity is high. Therefore, the pipes or pipe bends adjacent to the exhaust gas alley are prone to serious erosion. It has been proven in practice. The exhaust gas velocity in the tube bundle is 4 ~ 5m/s, and the flow velocity in the exhaust gas alley is as high as 12-15m/s, 3 ~ 4 times higher than before, and its erosion rate is tens of times higher, because the erosion rate of the tube is approximately proportional to the square of the smoke velocity.

6. What are the measures to prevent local erosion of the water heater?

- (1) Protective bricks: The heating surface that may be severely eroded can be covered with protective tiles, and only the eroded protective tiles need to be replaced during maintenance.

- (2) Protective curtain: Use protective curtains to protect the entire straight pipe or entire bend pipe in the exhaust gas alley and against the wall.

- (3) Use locally thick-walled pipes: When the pipes are densely arranged and difficult to install or replace protective tiles, a portion of the pipes with thick walls should be used in places where severe erosion may occur to extend the service life.

- (4) Exchange heating surface: Due to uneven wear, to make the heating surface of each part basically reach the same service life, the economizer adopts the flipping method, that is, the water heater is removed and flipped during overhaul, and then reinstalled (pipes not up to standard are replaced), so that the eroded surface lies behind the exhaust gas and the surface not washed by the exhaust gas is adjusted according to the exhaust gas flow rate, to reduce costs and improve the service life of the economizer.

7. What is the principle of operation and function of the water heater circulating tube?

The water heater circulation refers to the installation of a circulating tube between the bottom of the boiler body and the inlet pipe of the water heater. Its working principle is: in the initial stage of boiler ignition or during the shutdown process, when water supply is stopped due to the continuous flow of water, the water in the water heater circulation tube basically does not flow, the tube wall is not well cooled, and tube burning in the overheated area is easy to occur. If a circulating tube is installed between the boiler body and the water heater, when the water supply is stopped, the circulation valve can be opened, and the water in the water heater increases into the steam drum due to the low heat density, and the water in the steam drum can be continuously supplemented to the water heater through the circulation tube, thereby forming natural circulation. Due to the establishment of the water cycle, the heat of the water heater tube is taken away, which can effectively protect the water heater.

8. What is the impact of leakage inside the water heater circulation tube during normal operation?

If the water heater circulation tube leaks during normal operation, it will cause part of the water supplied to flow directly into the steam drum through the short-circuit path of the circulation tube and not flow through the water heater, this water is not heated in the water heater, and the water temperature is low, very likely to cause a temperature difference between the upper and lower parts of the steam drum to increase and create thermal stress, affecting the service life of the steam drum. In addition, the water passing through the water heater is reduced, and the flow rate is reduced without full cooling. Therefore, during normal operation, the isolation valve of the circulation tube must be tightly closed.

9. Why should a special shell be installed on the connecting pipe between the water heater and the boiler body?

This is because the water temperature at the outlet of the water heater may be lower than the water temperature in the boiler body. If the outlet pipe of the water heater is directly connected to the boiler body, thermal stress will occur near the nozzle of the boiler body due to the temperature difference. Especially when the working conditions of the boiler change, the outlet water temperature of the water heater may change dramatically, leading to intermittent stress and fatigue damage. After the shell is installed, the boiler body and the water supply pipe are filled with saturated steam or saturated water, avoiding direct contact between the water supply pipe and the steam drum with a large temperature difference, and preventing damage to the steam drum.