Naan - The first and only boiler manufacturing unit in Vietnam to apply 4.0 software in boiler management

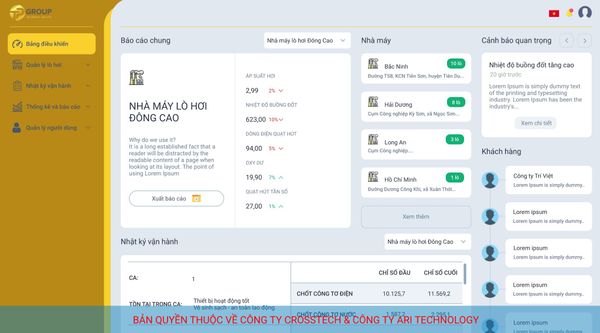

Remote computer control screen via the internet

Boilers are essential devices in industrial production, providing steam for various manufacturing processes. However, operating boilers poses many difficulties and challenges, requiring timely and accurate intervention by operators. To address this issue, Naan - a leading steam boiler manufacturer in Vietnam - has applied Industry 4.0 software in boiler management. This software is developed based on IoT and Information Technology platforms, enabling data collection from sensors installed on the boiler, thereby accurately and efficiently monitoring and controlling the operational parameters of the boiler. This article will introduce Naan's boiler management software and the benefits it brings to manufacturing plants.

1. Introduction to Naan's Boiler Management Software

Naan's boiler management software is an advanced technological solution, researched and developed by Naan based on IoT and Information Technology platforms.

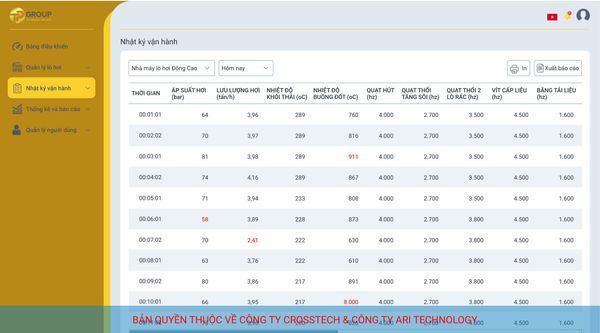

- This software allows data collection from sensors installed on the boiler, such as temperature, pressure, fuel consumption, exhaust gas volume, water supply, steam production, etc.

- This data is sent to the control center and displayed on the control panel in the form of charts, tables, graphs, etc.

- Operators can view, set, and monitor the parameters of the boiler, as well as receive alerts and error messages from the software.

- The software also allows operators to execute remote control commands, such as adjusting temperature, pressure, fuel consumption, etc.

- The software can also connect to the internet or internal network for data transmission and remote control.

2. Benefits of Naan's Boiler Management Software

Naan's boiler management software brings many benefits to manufacturing plants, including:

- Optimizing operational efficiency: The software helps automatically monitor and control the operational parameters of the boiler, minimizing errors and optimizing operational efficiency. The software also helps operators implement different operating modes of the boiler, suitable for the needs of each manufacturing process.

- Ensuring compliance: The software helps monitor the operational parameters of the boiler according to technical regulations, ensuring product quality. The software also helps operators check and maintain the boiler regularly, preventing damage and wear and tear of the boiler.

- Safety: The software helps detect potential issues early, preventing accidents. The software also helps operators handle emergency situations promptly, such as overheating, overpressure, leaks, explosions, etc. The software also reduces environmental pollution by reducing emissions.

Automatically recorded operation log, convenient for review and evaluation

3. Conclusion

Naan's boiler management software is an advanced technological solution, researched and developed by Naan based on IoT and Information Technology platforms. This software helps collect data from sensors installed on the boiler, accurately and efficiently monitoring and controlling the operational parameters of the boiler. This software brings many benefits to manufacturing plants, such as optimizing operational efficiency, ensuring compliance, safety, and environmental protection. Naan is a pioneer in applying Industry 4.0 technology in boiler production in Vietnam, contributing to enhancing the competitiveness and sustainable development of the industry.